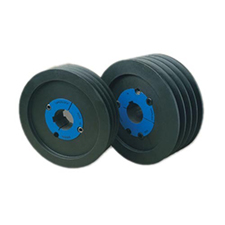

Industrial Belts Rotation HIC Drive Pulley Sheave

Classified under HS Code 8501

- Taper Bush Dynamically Balanced Dual Duty v belt pulley, A/SPA section 1 to 6 grooves 80~800mm pitch circle diameter (PCD) or Outer Diameter ; B/SPB 1 to 6 belt

grooved 125~1000 pcd ; C/SPC2~10 belts run groove 200~1250 mm PCD .

- Balanced Standard solid v belt pulleys General Purpose without taper bush A section 1 to 5 grooved 2~26 inch OD ; B section 1 to 5 grooves 2~40"od ; C section 3~8

belts groove 3~50" OD ; D section 3~12 belts groove 12~56" OD ; E section 5~15 belts grooved 16~72" OD.

- Taper Locking Bushes weld on hubs sizes 1008 to 5050 up to 125 mm maximum bore size.

- Toothed Drive Belt 'XL' type (extra light duty) pulley

- Cogged Belt 'L' type (light duty) pulley

- Tooth Belt 'H' type (heavy duty) pulley

- Cog Belt 'XH' type (extra heavy duty) pulley

- Toothed Belt 'XXH' type (double extra heavy duty) drive and driven pulley

HIC Universal V Belt Pulley, Weld on Hub Taper Bushing and Timing Pulleys are Original Choice by electric motor manufacturers and automotive

engine producers in India, Germany, UK, Australia, China, Mexico, USA North America, Canada, Latin America, Sweden, Russia, Japan, South Korea,

UAE, Scotland, Singapore, South Africa, Philippines, Indonesia, Saudi Arabia, Qatar, Azerbaijan, Sri Lanka and other Asian countries.

Shipping Time: Generally within 3-4 weeks or as stipulated in quote and accepted order.